YFK series efficient centrifugal pellet mill is our initiative patented product in China through meticulous research and development.

The pellet machine absorbed the essence of pellet mill in oversea market, its heart part “double-layer die” has unique structural assembly and ‘'rollers'' are made by high-abrasion-proof alloy steel and stainless steel, which improves the using life of spare parts greatly.

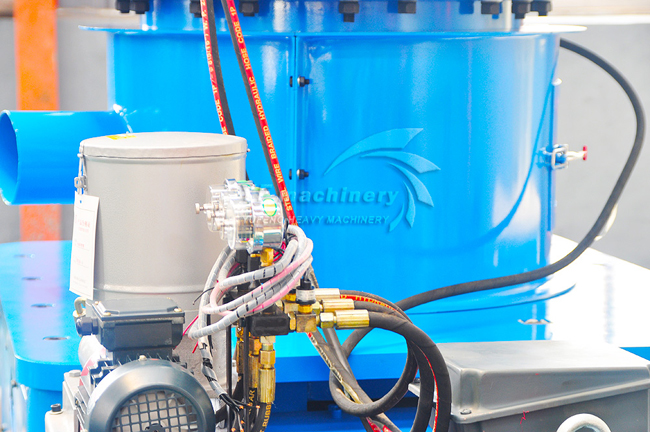

It has automatic lubricating system that the grease is injected and filtrated automatically, which can ensure the long time working without stop. It also has dust and cooling system that can reduce the dust during it working and improve the working environment.

Special design, rational structure, low power consumption and high efficiency, sturdy and durable, it achieves combining the advantage of both flat die pellet machine and horizontal ring die pellet mill and becomes the real professional pellet machine that is used to the materials with low adhesiveness and low shaping, such as the rice husk, sunflower husk, peanut shell and other fruit shell, branch, trunk, bark and other wood waste, a variety of crop straws, household waste, rubber, cement, ash and other chemical materials.

This type of pellet mill is widely used in the biomass-energy fuels plant, power plant, wood processing plant, MSW processing plant, fertilizer plant, chemical plant etc. It is the ideal pressing shaping equipments with low investment and high profit.

Technical parameter of YFK series efficient centrifugal pellet mill

Model |

Power(kw) |

Pellet size

(mm) |

Inch(mm) |

Production(t/h) |

Dimension(mm) |

Weight(t) |

| YFK500 |

55 |

Φ4-Φ12 |

500 |

0.3-1 |

2200x900x1600 |

3 |

| YFK550 |

75 |

Φ4-Φ12 |

550 |

0.7-1 |

2300x1000x1780 |

4.8 |

| YFK560 |

90 |

Φ4-Φ12 |

560 |

1-1.5 |

2600x1300x2300 |

5.8 |

| YFK580 |

160 |

Φ4-Φ12 |

580 |

1.5-2 |

2900x1300x2400 |

6.5 |

| YFK850 |

220 |

Φ4-Φ12 |

850 |

2-3 |

3750x1650x3250 |

12.6 |

| YFK880 |

315 |

Φ4-Φ12 |

850 |

3-4 |

4300x1900x3600 |

14.5

|

Product Characteristics

1.Vertical die,feeding vertically;No arching of raw materials,easy for heating dissipation.

2.Die fixed,rollers rotating,materials centrifugal,evenly distributed around.

3.Doulble-layer dies,up and down dual-use,high capacity,saving energy.

Particle finished products

To buy a pelletizer is far from enough for building a pellet plant. A typical pellet plant covers the following process: material resizing→material cleaning→drying→pelletizing→sieving & cooling→pellets packing.

wood pellet project diagram

To buy a pelletizer is far from enough for building a pellet plant. A typical pellet plant covers the following process: material resizing→material cleaning→drying→pelletizing→sieving & cooling→pellets packing.

wood pellet project diagram

Why choose YUFENG pellet plant?

First and foremost, YUFENG has it’s own ring die factory, meaning the all ring dies are made by us. We control the ring die quality so that we control the quality of pelletizer and eventually, the whole pellet plant, make it consistent and reliable. As a ring die decides the pellets quality made by a pelletizer and it is the most frequently changed wearing parts for a pellet plant, you definitely want to buy a durable and quality ring die to save money. Never buy from an unknown reseller because there will always be a huge mark-up and unpredictable quality. Below are the photos of YUFENG ring die workshop which deserves your trust. By the way, YUFENG ring die has the patented “step-shaped” die hole design, which triples the service lifetime of a ring die.

Strong production capacity

Why choose YUFENG pellet plant?

First and foremost, YUFENG has it’s own ring die factory, meaning the all ring dies are made by us. We control the ring die quality so that we control the quality of pelletizer and eventually, the whole pellet plant, make it consistent and reliable. As a ring die decides the pellets quality made by a pelletizer and it is the most frequently changed wearing parts for a pellet plant, you definitely want to buy a durable and quality ring die to save money. Never buy from an unknown reseller because there will always be a huge mark-up and unpredictable quality. Below are the photos of YUFENG ring die workshop which deserves your trust. By the way, YUFENG ring die has the patented “step-shaped” die hole design, which triples the service lifetime of a ring die.

Strong production capacity

Die forging station

quenching station

Heat treatment station

Certificate