Electromagnetic vibrating feeder

|

Brand: Yufeng |

| Certificate: ISO9001 , CE , IQNET , GOST |

| Advantage: provide reasonable product selection and design,scientific workshop manufacturing arrangements, strict production process,on time delivery |

Electromagnetic vibrating feeder

The electromagnetic vibrating feeder is a new type ration feeding equipment, which can meet the requirement of continuous production. Therefore, it has been widely used in mining, melting, coal, building materials, light industry, chemical, electronic, medicine and other industries.

| Item Model |

Feeding capacity(t/h) |

Object Max. allowed input size(mm) |

Power(w) |

Voltage(v) |

Current(a) |

Double swing(mm) |

Clearance(mm) |

Total weight(kg) |

| GZ1 |

5 |

50 |

60 |

220 |

1<= |

1.75 |

1.9-2.2 |

75 |

| GZ2 |

10 |

60 |

150 |

220 |

2.3<= |

1.75 |

1.9-2.2 |

155 |

| GZ3 |

25 |

70 |

200 |

220 |

3.8<= |

1.75 |

1.9-2.2 |

225 |

| GZ4 |

50 |

100 |

450 |

220 |

7<= |

1.75 |

1.9-2.2 |

460 |

| GZ5 |

100 |

150 |

650 |

220 |

10.6<= |

1.75 |

1.9-2.2 |

656 |

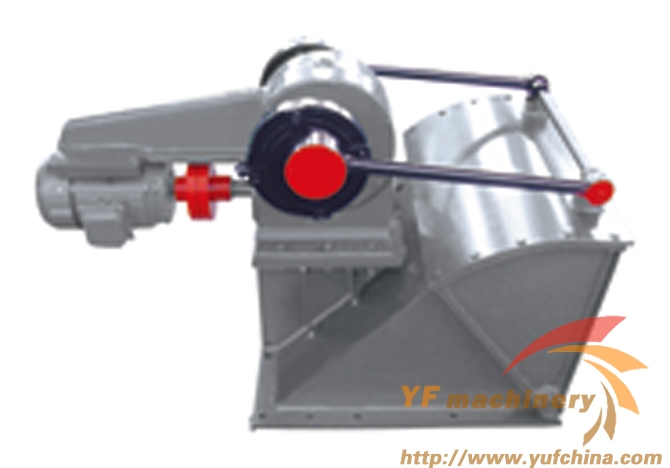

Swing Feeder

Swing Feeder is one kind for the ball mill collection ore belt type conveyer for the ore equipment;because the structure is simple, the ease of operation, the power consumption few, it may adjust evenly the quantity of mineral deposits, and it obtains the widespread application.

Swing Feeder is principle of work: After the electric motor starts, the power transmits the worm reducer to decelerate through the shaft coupling. (Must adjust the site of power wheel according to mineral quantity) Decelerating the power transmission, may adjust wheel ,then through the connecting rod, so as to make the obligation-suspending-ledger to arc-swing to and fro again, then causes ore mouth again and again opening from the surface closed; the ore machine pocket ore located for above, can pass the machine organism cavity, and the ore mouth, until discharges the outside of the aircraft with a uniform speed, and guarantees the ball mill evenly to the material production.

Technicial Parameters

|

Model

|

Entrance

size

(mm)

|

Exit size(mm)

|

Swinging(mm)

|

Swinging

frequency

(mm)

|

Max

Particle

size

(mm)

|

Productive

capacity

(t/h)

|

Motor

(kw)

|

Weiht

(kg)

|

|

300×300

|

300×300

|

300×125

|

0~90

|

68

|

100

|

8

|

1.1

|

213

|

|

400×400

|

400×400

|

400×50~150

|

0~170

|

47

|

35

|

12

|

1.1

|

272

|

|

600×600

|

600×600

|

600×150~150

|

0~206

|

45.5

|

50

|

25

|

1.5

|

558

|

Chute Feeder

The chute feeder is suitable for concentrating, coal, chemical and other industry department; the granular and piece materials are carried into different set from the storage bin, but not suitable for carrying the concentrate power and other power material.

Technicial Parameters

|

Model

|

Entrance

size

(mm)

|

Exit size

(mm)

|

Swinging

(mm)

|

Swinging

frequency

(mm)

|

Max

Particle

size(mm)

|

Productive

capacity

(t/h)

|

Motor

(kw)

|

Weight

(kg)

|

|

400*400

|

400*400

|

400*400

|

12

|

18.2

|

100

|

25-30

|

1.1

|

535

|

|

600*500

|

600*500

|

600*500

|

10-50

|

38.9

|

200

|

10-50

|

4

|

1054

|

|

980*1240

|

980*1240

|

900*800

|

20-50

|

23.7

|

350

|

36-90

|

7.5

|

1676

|

Welcome to Zhengzhou YUFENG Machinery Company.If you want to more information about our Electromagnetic vibrating feeder,Chute Feeder,Swing Feeder, Please give us the message, we will reply as soon as possible.

|

|